These passive safety systems must undergo various tests to be installed in vehicles. Most of the tests are carried out through destructive tests and are accompanied by all phases of airbag production. The static test system is used to test the quality of the assembly airbag module. This method USES the static deployment test (SDT), which is explained below.

When the test was triggered by a computer command, the test header was reduced to a test object almost without friction. Impact delay is measured by integrating two acceleration sensors in the test head.

The arithmetic mean of the two sensors was then evaluated as test results.

The impact velocity of the head on the sample is detected by two grating and the two grating are installed at a distance. A third light barrier can selectively light one or more airbags. If needed, air balloon pressure can be measured using air pressure sensors installed in the test sample container during ignition.

Can use high-speed cameras to monitor and optimize the head impact test, and you can also determine the relative to the speed of ignition timing and tear and aeration time, record this in memory of up to 20000 images per second. The output of the digital stored image information is executed through the video screen, and the data is back up to video logger or dvd-rom. The camera's record begins with the ignition of the airbag module.

SDT software decides to use Windows applications. The surface makes the operator familiar and easy to handle. In doing so, the software requirements that occurred during the airbag test were not ignored. It is used to analyze single-stage or multi-stage airbag systems under the same conditions as actual vehicles. This method considers the maximum possible variability, which is reflected not only in the functionality of the product but also in the storage of the measured data. For example, measurement data can be optionally stored in all common formats (e.g.,.dbf,.xls) for additional processing with other programs. Measure, calculate.

Ambient temperature, 2 or 4 wire fuse resistance

The ignition current/ignition voltage is f (t), i.e. ignition time, ignition current, ignition voltage and ignition energy

Tearing time (tearing open cap), airbag inflating time,

Stretching and compression produced by the expansion of the wheel hub,

Air balloon internal pressure measurement/temperature measurement,

Long-term temperature sensing

In addition, the high-speed camera can be optionally used for analysis and research and to determine the time of tear or inflation relative to ignition time. The image can be read directly to the computer through the interface to determine the inflatable time of the airbag and so on. To do this, include an image assessment software integrated into the existing interface to avoid unnecessary program changes. This provides the possibility of subsequent processing of available image materials, such as contrast or brightness changes. In addition, text messages and graphics can also be inserted into video. Quartz control recording rate allows precise timing of processes directly related to ignition triggering

To meet the requirements of the document, you can convert any format's digital stored image information into a standard AVI format and store it in any known media (CD and DVD drive, etc.).

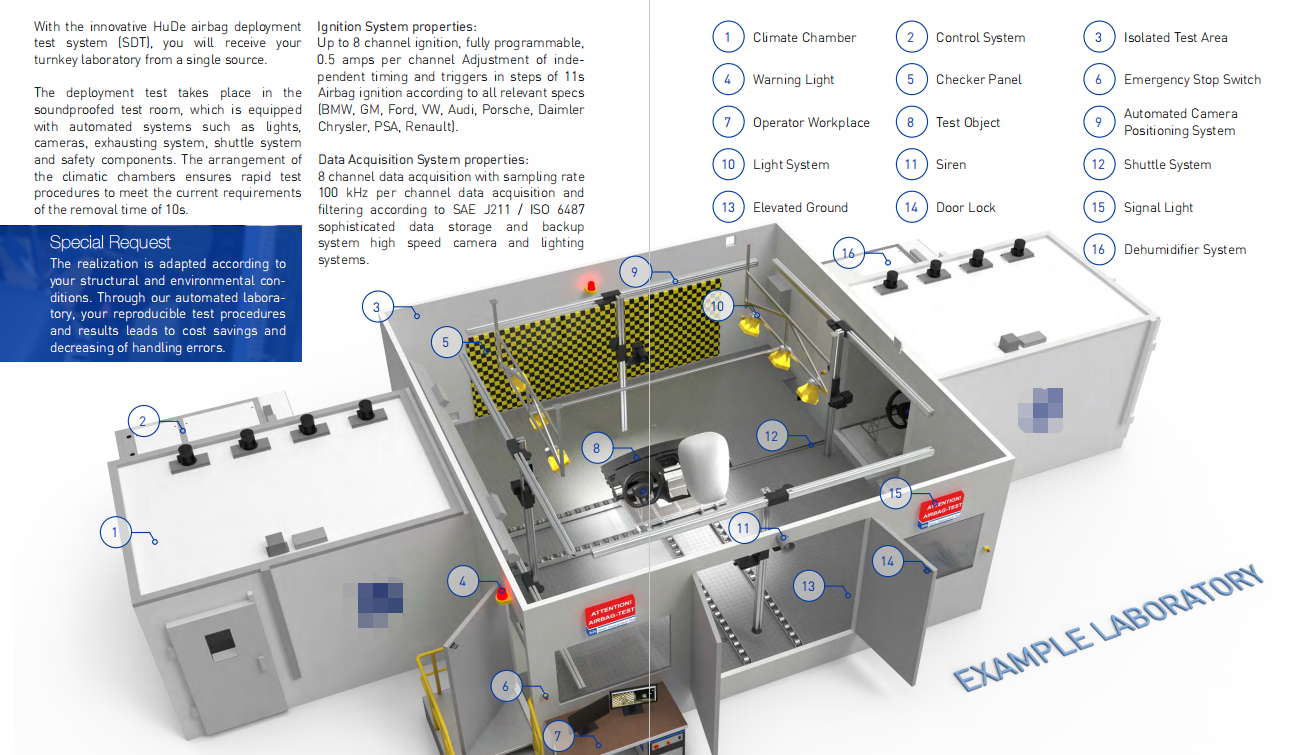

The user who has been authorized by the id card reader is printed on the front page for a complete check. The door of the test chamber is automatically closed and the camera is taken to the predetermined position by the positioning system. The specimens are driven by a shuttle from the automatic climate chamber and are allowed to be tested at different temperatures. The lighting system has been opened. By turning the key switch, the test piece will get the ignition pulse when the camera starts recording at the same time.

After the test, the camera stops recording, the lighting system shuts down, and the room exhausts the scheduled time. Only in this way can the access door be released again. The program now stores the bar code of the component, the measurement value, all the experimental data and test Settings specified by the operator to ensure the integrity of the document. This method enables the playback performance of the test process to achieve comparable results at any time. Test evaluation is directly possible because the measurements are immediately exported on the screen. However, the application of software is not limited to airbag expansion test, but can be applied to test belt tensioner or belt restraint system.